Facilities Melting

Medium frequency Induction Melting Furnace manufactured by Inductotherm (India) Pvt, Ltd, Bhopal, 200 KW with two crucibles of 500 Kgs and 150 Kgs.

3 & 1 MT EOT crane – Movement from the furnace to 20 meters at main bay.

S.G. Treatment laddle – 3 Nos. (Capacity – 900)

Cupola 1.5 MT Per Hour – 1 No.

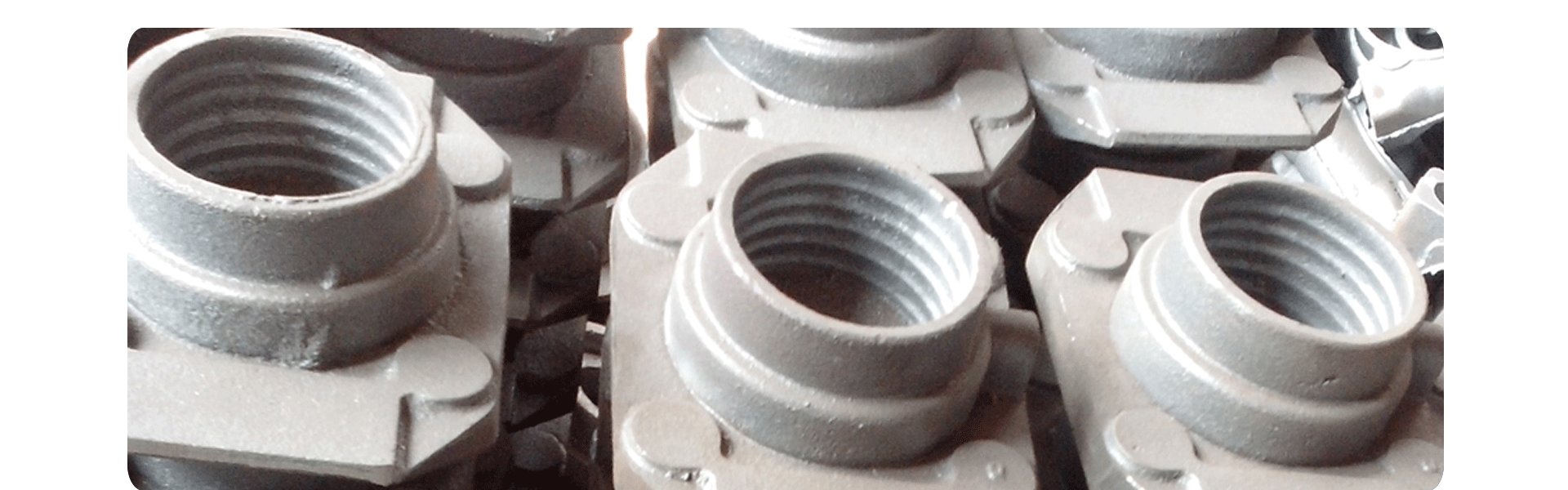

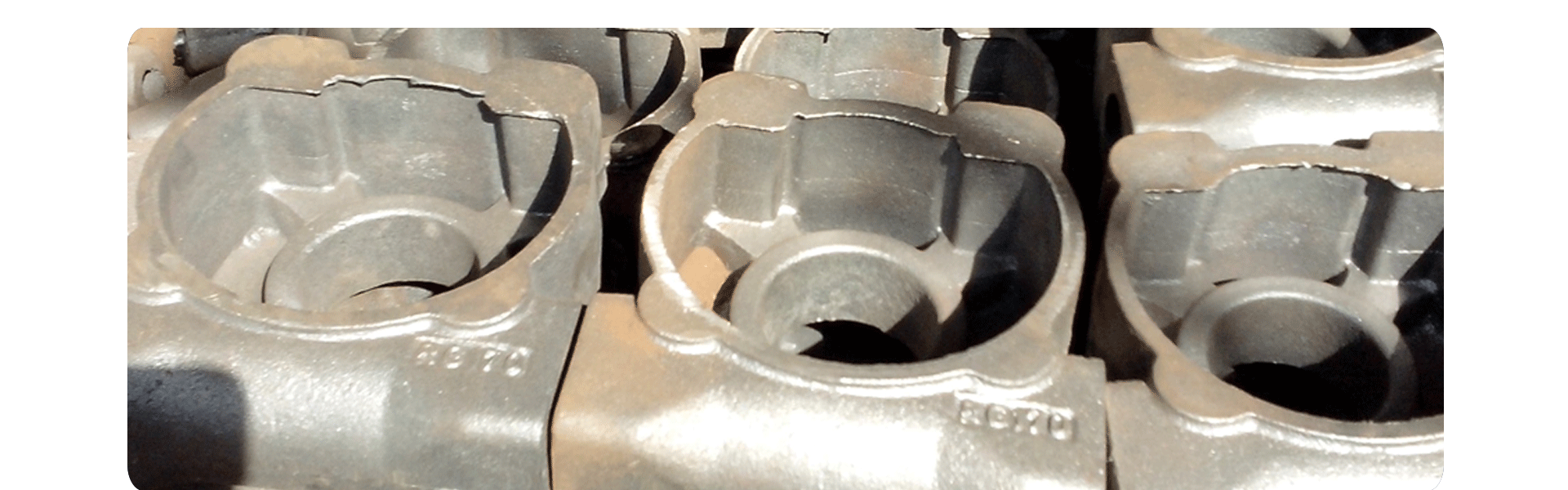

Moulding

Process

Hand Mould (Green Sand&Co2), Machine Mould (Green Sand).

Machine Mould

- Arpha 300 type Moulding machine: 1 Pair

- Muller - 450 Kgs. Capacity: 1 No

- Sand sieving vibrator with skip charger: 1 No

- Compressor- 25 HP : 1 No

- Compressor- 7.5 HP : 2 Nos

- C.I. Mould Box 400 x 520: 90 Sets

- C.I. Mould Box 520 x 520: 20 Sets

- Alu box 520x520 (cake type) : 5 Sets

- Track line for 28 boxes in 4 tracks each)

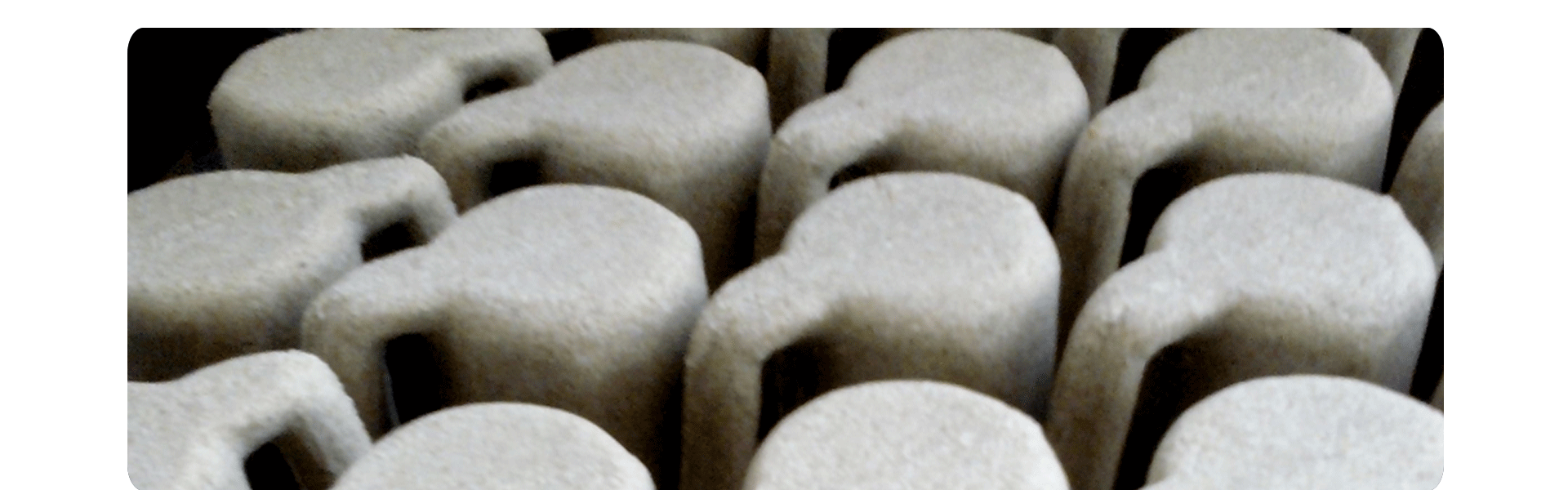

Core Making

Sand Mixer – 150 Kgs Capacity – 1 No..

Cleaning and Finishing

- Shot blasting M/c.

- Swing Frame Grinder

- Die Grinder

- Flexible Shaft Grinder

- Bed Grinder

- Gas Cutting Machine

- Welding Rectifiers

Laboratory for Testing

Suyash CE IInd level meter – facilities to read tensile and compression value, hardness, carbon equivalent, carbon and silicon – installed on the melting platform

Wet Lab

- Carbon - Sulphur apparatus

- Muffle Furnace

- Hot Plate

- Microscope

- Polishing machine

- Brinell Hardness Tester

- Analysis of following elements with available apparatus Carbon, Silicon, Manganese, Phosphorous, Sulphur, Chromium, nickel and Copper

Power

- TNEB supplies - 300 KVA (to be increased to 325 KVA shortly)

- Diesel Genset - 250 KVA.

- Diesel Genset - 62.5 KVA to be used incase of emergency

Capacity

Spare Capacity

Foundry is equipped to manufacture 300 Mts of Grey Iron and S.G. Iron Castings per month at the rate of 60% average yield.